|

In what follows a few examples for

imaging dislocations with TEM are shown. Where possible, examples have

been selected that have been used before (e.g. in the context of dislocation

loop formations) or will be used later (e.g. in the context of defects in

boundaries). |

|

The first example demonstrates the

contrast of dislocations as a function of the excitation error |

|

|

|

|

|

|

|

|

|

|

The specimen was bent a little; so the excitation

error changes from left to right. On the left hand side, the excitation error

is relatively large; on the right hand side it is small. The contrast on the

left is weak, but the resolution is good; on the right hand side the

dislocation appears a as strong, but blurred black line. |

|

The second example demonstrates the

contrast disappearance for g · b = 0. |

|

|

Shown is a network of pure screw dislocations in

Si which we will encounter again in the context of grain

boundaries. |

|

|

|

|

|

|

|

|

Only one set of dislocations shows up

in the dark field conditions employed for the g = {220} type of

diffraction vector which is parallel to one Burgers vector and perpendicular to

the other one. With a g = {400} diffraction vector both sets of

dislocation are imaged, but there is a loss of clarity. |

|

Next we will see how a dislocation

loop can be analyzed. |

|

|

Shown are dislocation loops of the "A-swirl defects" imaged

with two different diffraction vectors (drawn in as arrows) and a

+g/–g pair. In the first image, the contrast of the lower

dislocation loop has disappeared (the fuzzy line is due to the precipitates

along the dislocation line). The two pictures on the right show the lower loop,

the image is wide or narrow, depending on the sign of the diffraction vector

g. |

|

|

|

|

|

|

|

|

|

|

|

This is an important effect because it allows to

analyze the nature of a dislocation loop as schematically illustrated below.

The image of the loop lies inside or outside the geometric projection; upon

reversing the sign of g or b (and this means switching from

vacancy to interstitial type), the image switches between the two

extremes. |

|

|

|

|

|

|

|

|

|

|

|

For a given geometry it is possible to predict if

the contrast is "inside" or "outside"; the nature of a loop

may thus be determined. But beware! There are many possibilities of committing

a sign error! Printing the negative with emulsion side up or down, e.g., will

exchange the signs and turn a vacancy loop into an interstitial loop or vice

versa. |

|

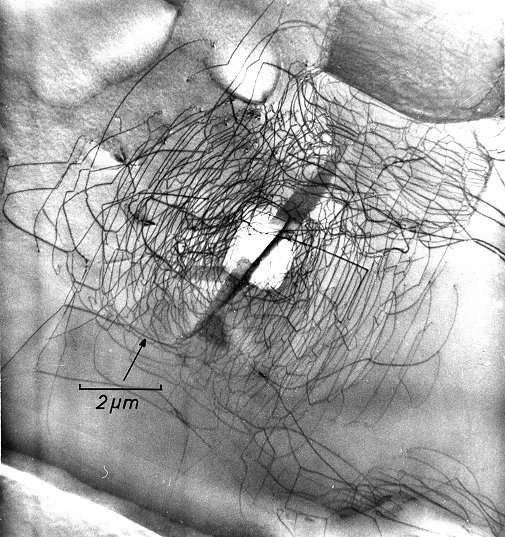

The next example compares regular

dark field and weak-beam conditions. The object is a very dense dislocation

network with a complicated structure which we will encounter again in the

context of grain boundaries. |

|

|

|

|

|

|

|

|

The weak-beam image on the left shows a lot more

detail, but the signal to noise ratio is rather bad. This is about the limit of

the resolution obtainable under weak beam conditions. |

|

|

In the link, a

comparison between weak-beam

conditions and bright field can be found. |

|

The last picture shows conventional

bright field imaging. |

|

|

The tip of a probe produced some mechanical damage

in the emitter area of a transistor in an integrated circuit (the bright square

area in the center of the tangle). A microcrack was generated (the elongated

black shape); upon heating in the next processing cycle the dislocation tangle

was formed to relieve the stress. |

|

|

|

|

|

|

|

|

|

|

|

By tilting the specimen while keeping the imaging

conditions constant (this involves a rotation around the diffraction vector), a

second picture can be obtained under a somewhat different imaging direction.

The two pictures can be viewed in a stereo viewer and will produce the full

three-dimensional glory of the structure. |

|

More examples can be found in the

links |

|

|

Weak-beam image of a dislocation network

involving partial dislocations under different diffraction conditions

Unknown ribbon defect in

Si, showing difficulties in interpretation

Radiation damage in

Co showing possibilities of interpretation

FeSi precipitates in

Si

Prismatic punching of

dislocation loops from precipitates

Helix dislocations produced

by climb of screw dislocations

Dislocations in TiAl

being pinned by debris

PtSi on Si

showing the power of diffractions

patterns (for

another

example use the link)

Comparison weak beam - bright

field |

© H. Föll

© H. Föll